LCP Film: Enabling 5G, Wearables, and Aerospace Advances

1. Introduction

Liquid crystal polymers (LCPs) are high-performance materials known for their fluidity and molecular order in liquid crystal phases when heated or dissolved. These polymers feature rigid, rod-like molecular chains, which provide exceptional high-temperature resistance, dielectric stability, and dimensional reliability. Since their introduction in the 1970s, LCPs have been integral to innovations in electronics, telecommunications, and industrial manufacturing.

LCPs are categorized by thermal and processing properties, with specific types optimized for distinct applications: Type I for high-temperature electronic components, Type II for antenna materials, and Type III for connecting tubes and sensors. Among LCP grades, films exhibit standout electrical and mechanical characteristics such as low dielectric constants (2.9–3.5), minimal water absorption, excellent thermal stability (heat deflection temperatures of 250–320°C), and high tensile strength. These properties make LCP films ideal for high-speed, high-frequency applications, including 5G mobile antennas, wearable circuits, and aerospace communication systems, where efficiency and reliability are paramount.

2. Overview of LCP Films

LCPs are advanced materials with molecularly ordered structures in liquid crystal phases under heat or dissolution. Their rigid, rod-like molecular chains impart high-temperature resistance, excellent dielectric properties, and dimensional stability. Since their commercialization in the 1970s, LCPs have diversified into forms like solvatochromic, thermochromic, and piezotropic liquid crystals, with thermochromic types being the most common.

LCP products are available in injection molding, film, and fiber grades, further categorized into Type I, Type II, and Type III based on synthetic monomers. Each type caters to different needs:

- Type I: High heat resistance, ideal for electronic components.

- Type II: High heat resistance and processability, suited for antenna materials.

- Type III: Lower heat resistance, used for connecting tubes and sensors.

LCP films excel in high-speed, high-frequency settings due to their low dielectric constants (2.9–3.5) and minimal water absorption (<0.04%). With a low coefficient of thermal expansion (10–17 ppm/°C) and heat deflection temperatures of 250–320°C, they maintain stability under extreme conditions. Their tensile strength (150–300 MPa) and Young's modulus (10–25 GPa) ensure performance even in high-temperature environments, making them invaluable in advanced electronics.

Fig. 1 LCP Films

3. Applications of LCP Films

3.1 Flexible Wearable Circuits

LCP films combine excellent dielectric properties with flexibility, enabling the creation of compact, durable circuits for wearable devices. Their low dielectric constant and loss tangent ensure high signal integrity in applications like fitness trackers and smartwatches. Additionally, their lightweight and chemical resistance enhance user comfort and durability under various conditions.

Fig. 2 Flexible Wearable Circuit

3.2 5G Mobile Phone Antennas

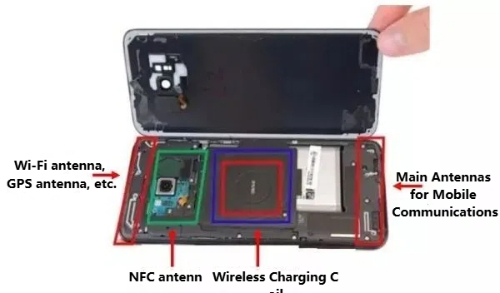

LCP films are ideal for 5G antennas, offering low dielectric constants and loss tangents for superior signal integrity in millimeter-wave bands. Their thermal stability and mechanical strength support compact, high-performance designs that withstand environmental stress while ensuring reliable high-frequency communication.

Fig. 3 Cell Phone Internal Antenna

3.3 Large Aircraft RF Antennas

In aerospace, LCP films meet stringent demands for RF antennas, providing low signal loss, wide frequency support, and thermal stability. Their lightweight, flexible nature and resistance to environmental factors make them perfect for reliable communication systems in modern aircraft.

Fig. 4 Radio Frequency Antenna

3.4 5G Millimeter-Wave Radar Communication

LCP films enhance 5G millimeter-wave radar by delivering low dielectric loss and high-frequency stability, essential for efficient data transmission. Their mechanical strength and flexibility support compact, durable designs for advanced radar systems.

Fig.5 Communication Radar Base Station 5g Device Signal Transmission

3.5 5G Base Station Flexible Transmitter Units

LCP films excel in 5G base stations, optimizing signal paths with their low dielectric loss and flexibility. Their thin, lightweight nature supports device miniaturization, while their stability ensures consistent performance in outdoor environments.

Fig. 6 5G Base Station

4. Conclusion

LCP films are versatile materials that address the rigorous demands of modern electronics, telecommunications, and industrial systems. Their dielectric properties, thermal stability, and mechanical strength enable high-frequency signal integrity, miniaturized designs, and flexible circuits in applications like wearable electronics, 5G antennas, and aerospace communication systems. As technology continues to advance, LCP films remain a cornerstone for high-performance solutions.

Stanford Electronics is a trusted supplier of high-quality LCP films, providing reliable solutions for these cutting-edge applications.